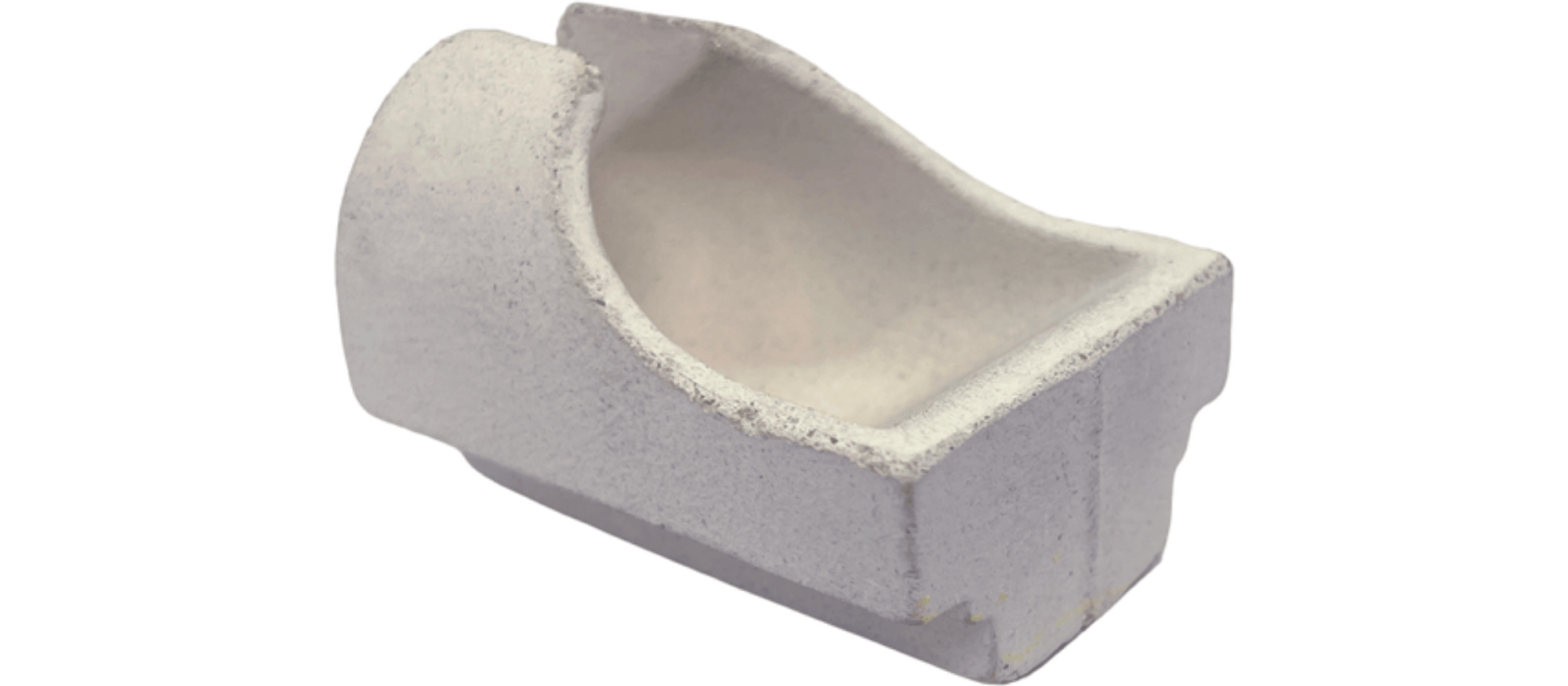

BESQUAL - Casting Crucibles - Clay-S (Clay / Slotted) - # 718-001

Description

PRODUCT DESCRIPTION

Our non-contaminating clay or quartz Casting Crucibles are built to withstand extreme heat for melting both precious and non-precious metals. Their universal design ensures compatibility with all standard and broken arm centrifugal Casting machines.

ORDER CODE

ITEM NUMBER

SIZE (mm)

MATERIAL / TYPE

MAX. TEMPERATURE

CLAY S

718-001

63.20 x 48 x 42.50

Clay / Slotted

1,000°C / 1832°F

MORE DETAILS:

Slotted Crucible:

Design: Open with one or more vertical slots along the side.

Primary Use: Often preferred for non-precious alloys and those with higher melting points. The slotted design is thought to:

Improve alloy flow: The slots may facilitate a more even and less turbulent flow of the molten metal into the mold during centrifugal Casting.

Offer better visibility: The open slots allow for easier visual inspection of the melting process.

Potentially handle larger volumes: Depending on the design, slotted Crucibles might be better suited for larger quantities of metal.

Pouring: The molten metal exits through the slots during the centrifugal force of the Casting machine.

Hooded Crucible:

Design: Enclosed or partially enclosed with a small opening or spout.

Primary Use: Generally recommended for precious or semi-precious alloys and those with lower melting points. The hood helps to:

Retain heat more effectively: This can lead to faster and more energy-efficient melting, especially for smaller quantities of metal.

Minimize oxidation: The reduced exposure to air helps prevent the formation of oxides on the surface of the molten metal, preserving its purity and reducing material loss.

Reduce splashing: The enclosed design helps contain the molten metal during the centrifugal Casting process.

Pouring: Pouring is typically done through a designated spout or the main opening.

Feature

Top Design

Heat Retention

Oxidation

Splashing

Alloy Flow

Visibility

Common Use

Hooded Crucible

Closed or partially covered with an opening

Generally better

Minimized due to less air exposure

Reduced

May be more direct through the opening

Limited

Precious/semi-precious, lower melting points

Slotted Crucible

Open with vertical slots

Less effective

More potential for oxidation

More potential for splashing

Potentially more even/less turbulent through slots

Better visibility of the melt

Non-precious, higher melting points